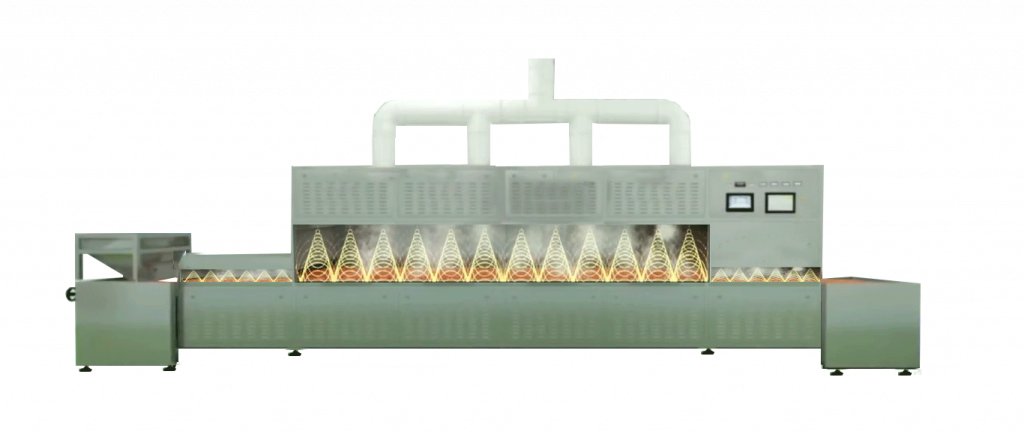

Microwave Tunnel Dryer

——Continuous and rapid drying

Microwave tunnel dryer is a continuous microwave drying equipment, which can be widely used in the drying of food, chemical industry, pharmaceutical intermediates, wood, pet food, etc. It is suitable for drying flakes, strips, granules and paste materials. The tunnel dryer has compact structure, easy installation, long-term operation and convenient maintenance.

01 What Are the Advantages of Using Industrial Microwave ?

1. Microwave heating has a fast drying speed and save time.

2. Drying effect is good with high product quality.

3. Microwave drying evenly from beginning to the end.

4. The thermal radiation process with automatic balance performance.

5. Save labor and easy to operate.

6. Microwave drying and sterilization thoroughly at the same time.

02 How does industrial microwave oven work ?

An industrial microwave dryer works in the same way as when we heat food in a household microwave oven. The microwaves cease at the same moment as the drying machine or microwave oven is switched off. The drying method is based on microwaves penetrating the moist products, where the microwaves are converted into heat. The moisture turns into vapor and is transported from the dehumidification pipe.

Prepare the products, when the products that need to be dried are loaded into the hopper, they will flow onto the conveyor belt automatically, or the products can also be spread directly on the conveyor belt. The height of the conveyor belt from the ground and the width of the conveyor belt can be customized according to the product.

After turning on the microwave tunnel dryer, the product will be transported to the inside of the machine along with the conveyor belt. During the whole process from the product entering the heating area to exiting the machine, the water molecules inside of the products will rotate as they try to align themselves with the alternating electric field induced by the microwave rays. The rapid movement of the polar molecules creates friction and results in heat dissipation in the material exposed to microwave radiation.The moisture in the product is constantly evaporating due to the continuous heat generated.

During the drying process, the water vapor generated will be pumped away from the pipes by the exhaust fan. The pipes and fans can be reasonably arranged according to the space of the plant. According to actual requirements, recovery devices and dust removal devices can be installed.

After drying, the dried product can be obtained at the outlet. If the product needs to be packaged after cooling, the cooling zone can be increased to cool the product.

The whole drying process is continuous. New products are continuously added at the feed inlet, and dried products can be continuously obtained at the outlet. Therefore, the microwave dryer can be easily connected with other equipment and assembled into an automated production line.

03 What products can be dried by industrial microwave oven ?

We provide customers with machines in food drying, chemicals drying, spice drying, herb drying, wood drying, plaster drying, worm meals drying, paper products drying, ready meals heating, and so on.

strength.

Industrial microwave ovens are widely used, but specific to the drying of each product, the drying process used is different. That’s why we say machines can be customized, and it’s also our strength.

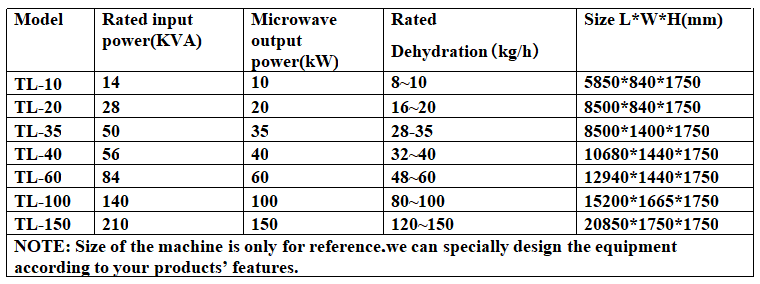

04 What are the technical parameters of microwave tunnel drying machines ?

We have more than 30 models of CE certificated machines,power from 6kw to 500kw,machines can be made according to your product,voltage and other specifications. Some models for reference:

05 Is your microwave tunenl dryer safe ?

Yes, our microwave tunnel dryer is safe, which is something we have to consider from the very beginning of the design. Whether the microwave is safe or not depends on how we use it. Our engineers have considered the microwave from the structure of the machine, from the connection of the box, the door, the exhaust and humidity system, the operating system, to the front suppressor/rear suppressor, etc. Ensure that any position close to the machine is safe (the international standard for microwave leakage is less than or equal to 5mW/cm2), our standard fully meets the requirements, and every machine that leaves the factory has undergone our strict inspection.

06 Tunnel Dreyr Applications

There are many applications of tunnel dryers, and products in almost any state can be dried. You can refer to the following real cases to understand the of tunnel dryer applications.

Spice Powder Drying By CE Certificated Continuous Microwave Tunnel Dryer

It uses microwave energy to heat the powder to a particular temperature and it makes the powder dry very fast. The high-efficiency drying method also allows the powder to dry at a very high rate. Using the high-efficiency drying method without any wastage.

Black Soldier Fly Larva / Mealworm Drying With Microwave Tunnel Dryer

Mealworms are extremely resilient and can withstand low temperatures for long periods of time. However, they do not do well in very hot or very cold temperatures. This is because they lack moisture, and in extreme temperatures lose their ability to absorb nutrients, including protein. A mealworm drying machine works by drying off the mealworms before they reach these extreme temperatures, resulting in them being dried ready as quickly as they come out from the outlet.

Tea Leaf Drying By Microwave Tunnel Dryer

Tea leaves can be dried as desired. The question is, how are they dry by microwave? To answer this question, we have to take a step back and consider what we want to achieve from drying these leaves. We are looking for a good taste in our tea or coffee and we don’t want to risk destroying the leaf’s colour or aroma. By drying leaves by microwave we will achieve all of these goals. More Less